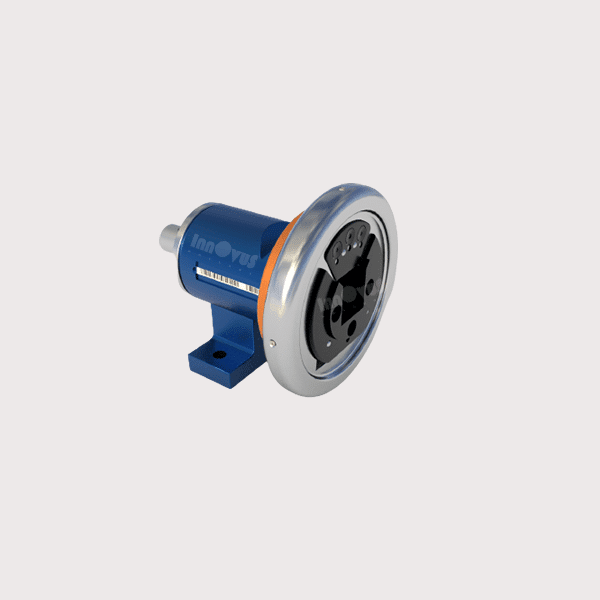

Safety Chuck

Major Manufacturer, Supplier, and Exporter of Safety Chucks

Safety chuck is square bar holder and mainly used in the shafted centre to wind and unwind applications. As the driving mechanism, it does not need to be removed every time while changing the core holding shaft, as it gives maintenance free working. We are the best safety mounting chuck manufacturer since long, situated in Ahmedabad, Gujarat with word-class machinery and infrastructure. Each chuck is going through various processes for assuring best in class quality and low maintenance. We are always committed to providing on-time delivery and 24*7 service support to our clients.

Our company offers a wide range of safety chunks, such as Base Mounted Safety Chunk, Boschert Safety Chunk, Flange Mounted Safety Chunks, Square bar holding safety chunks, Tilt type safety chunks, Boschert Safety Chunk Manufacturers, etc in India. The constant search for innovative and cutting-edge solutions has allowed us, over the years, to increasingly expand our market and satisfy the most varied needs and demands of customers from all over the world. And it is precisely from a specific need of one of our customers that the latest innovation has developed here at Innovus Roller. The safety chucks can now be equipped with mechanical and electromechanical sensors to be able to verify if the safety chuck is open or closed, thus drastically improving safety.

We manufacture & export safety chunks:

- Safety Chuck Manufacturer in Ahmedabad

- Safety Chuck Manufacturer in Chennai

- Safety Chuck Manufacturer in Delhi

- Safety Chuck Manufacturer in Kolkata

- Safety Chuck Manufacturer in Mumbai

- Safety Chuck Manufacturers in India

- Safety Chuck Manufacturer in Pune

- Safety Chuck Manufacturer in Bangalore

- Safety Chuck Manufacturer in Hyderabad

- Safety Chuck Manufacturer in Indore

- Safety Chuck Manufacturer in Jaipur

- Safety Chuck Manufacturers in Kerala

Properties:

- For less downtime during the turnaround, it provides a quick change at the end of a production run (either winding or unwinding), making the operation more cost-efficient.

- It provides a passage of transmitting torque to the winding/unwinding roll.

- Provide for concentricity between the centerline (axis) of the Safety Chuck and the roll shaft centerline.

- Helps obtain less eccentricity between the roll shaft and the Safety Chuck, so less vibration and abrasion/wear

Advantages:

- Turning ball bearings made with great precision

- Chrome plated with a handwheel made of steel.

- Constructed of cast iron housing & durable

- Redundant handwheel lock mechanism

- Shaft extensions with keyway

- Finger guards on all models to ensure the safety of workers

- The hardness of shaft sockets up to Rockwell 56C

- Available in tilt plate or Slide ring handwheel models

- Comes with either foot or flange mounting

- “U,” “V” or “VO” types inserts & replaceable too

Related Keywords:

- Pneumatic safety chucks

- Industrial Safety Chuck Manufacturer

- Polished Safety Chuck Manufacturer

- Base Mounted Safety Chunk Manufacturer

- Flange Mounted Safety Chunk

- Flange Mounted Safety Chuck Manufacturer

- Sliding Type Safety Chuck

- Square Bar Holding Safety Chunk

- Tilt Type Safety Chunk

- Boschert Safety Chunk Manufacturer